GARRARD SPRING MOTOR SPECIFICATIONS

Quick Reference Table

Thank You!!!

Firstly, I would like to thank all the people who have helped me compile these gramophone motor pages. It would not have been possible without their help, hard work and generosity. They provided pictures, illustrations and a mountain of invaluable information. Christopher Proudfoot, Graham Rankin, Roger Mackey and Francis James.

Pointers:

- Dates are subjective and are taken from advertisement and dated catalogues

- Spring sizes and information is taken from an October 1954 Vulcan mainsprings catalogue re-printed in Talking Machine Review 22. It can be downloaded here at Archive.com. Spring ends are pictured below. Other spring manufacturers like EMO and Selecta have varying lengths for the same motor

- Governors:

- Early governors were the simple three ball type

- Garrard patented their own in 1927/28 having angled mounting bearings

- Improved patent in 1929: It had flattened balls screwed onto the inside of the governor springs

- 1930 patent: Garrard introduced the clip-on governor spring which reduced price by eliminating screws and was a significant improvement reducing "racing governor" where an un-ballanced set of three governors would set the motor shuddering

Pictures in gallery below

- Governor control methods:

- DIAL: A springed friction pad controlled by a lever below the motorboard. The lever raised and lowered by a dial mounted on top of the motorboard

- LEVER: Governor adjustment mounted on the side of the frame with a twist rod. An extra hole was drilled in the motorboard and an above motorboard lever ran under the turntable to a speed control plate

- TWIST: This method introduced in the Junior B: All later models have this system. It worked like the lever method above the motorboard. "..not really an improvement, just a cheaper and simpler system. In theory, it would give a less progressive control of speed, because it works by twisting the friction pad, so that the area in contact with the disc will alter significantly when the lever is moved." Christopher Proudfoot

Pictures in gallery below

- Early motors often had expensive solid steel base plates. These were replaced with thin pressed steel plates which reduced costs and also provided more room for governor expansion

- Please contact me for any corrections or errors

- Early governors were the simple three ball type

- Garrard patented their own in 1927/28 having angled mounting bearings

- Improved patent in 1929: It had flattened balls screwed onto the inside of the governor springs

- 1930 patent: Garrard introduced the clip-on governor spring which reduced price by eliminating screws and was a significant improvement reducing "racing governor" where an un-ballanced set of three governors would set the motor shuddering

- DIAL: A springed friction pad controlled by a lever below the motorboard. The lever raised and lowered by a dial mounted on top of the motorboard

- LEVER: Governor adjustment mounted on the side of the frame with a twist rod. An extra hole was drilled in the motorboard and an above motorboard lever ran under the turntable to a speed control plate

- TWIST: This method introduced in the Junior B: All later models have this system. It worked like the lever method above the motorboard. "..not really an improvement, just a cheaper and simpler system. In theory, it would give a less progressive control of speed, because it works by twisting the friction pad, so that the area in contact with the disc will alter significantly when the lever is moved." Christopher Proudfoot

You can download this list as an Excel spreadsheet or a PDF.

| Model | Date | Frame | Governor | Features | Spring # | Width x Thickness | Spring Length | Outer End | Inner End | Image |

|---|---|---|---|---|---|---|---|---|---|---|

| Garrard 1 | 1919 | Cast with flat steel base plate | Ball. Dial controlled | Square-tooth gears on the spring case winder | Double | 1" x 0.024" | 13' 3" | Pear shape | Hole | |

| Garrard 1a | Feb 1922 | Cast with flat steel base plate | Ball. Dial controlled | Helix gears on the spring case winder. Improved ratchet winder | Double | 1" x 0.024" | 13' 3" | Pear shape | Hole | |

| Garrard 2 | Feb 1921 | Cast iron | Ball. Dial controlled | Heavy, long spring | Single | 1" x 0.024" | 16' | Pear | Hole | |

| Garrard 3 | Feb 1921 | First pressed-steel frame | Ball. Dial controlled | Ideal for portables | Single | 1" x 0.024" | 7' 5" | Pear shape | Hole | |

| Garrard 4 | March 1922 | Pressed-steel frame | Ball. Dial controlled | Machine cut gears | Double | 1" x 0.024" | 7' 5" | Pear shape | Hole | |

| Garrard 4a | April 1923 | Pressed-steel frame | Ball. Dial controlled | Improved speed control | Double | 1" x 0.024" | 7' 5" | Pear shape | Hole | |

| Garrard 9 | April 1923 | Pressed-steel frame | Ball. Dial controlled | Improved rachet wind | Single | 1" x 0.024" | 11' 6" | Pear shape | Hole | |

| Garrard 8 | Nov 1924 | Enamelled Cast | Ball. Dial controlled | Improved bearings | Single | 1" x 0.024" | 11' 6" | Pear shape | Hole | |

| Garrard Super | 1924 | Cast with flat steel top plate | Ball | Sealed Oil Bath Motor | Double | 1” x 0.026" | 16' 9" | Pear | Hub | |

| Garrard / Columbia 5 | 1925 | Cast iron | Ball. Dial controlled | Slotted crank. Oil channels | Single | 1" x 0.024" | 13' 3" | Pear | Hole | |

| Garrard / Columbia 5a | 1925 | Cast iron | Ball. Dial controlled | Screw-in crank | Single | 1" x 0.024" | 13' 3" | Pear | Hole | |

| Garrard / Columbia 6 | 1925 | Cast frame and base plate | Ball. Dial controlled | Vertical mounted spring barrels | Double | 1" x 0.026" | 12' 6" | Pear | Hub | |

| Garrard / Columbia 7 | 1925 | Cast frame and base plate | Ball. Dial controlled | Oil sump and wick | Triple | 1" x 0.028" | 16' | Pear | Hub | |

| Garrard / Columbia 7a | 1925 | Cast frame and base plate | Ball. Dial controlled | Oil sump and wick | Triple | 1" x 0.028" | 16' | Key Hole | Hole | |

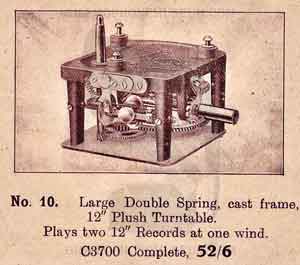

| Garrard 10 | 1927 | Cast with flat steel base plate | Ball. Dial controlled | Winder in middle of frame | Double | 1" x 0.024" | 11' 5 ½" | Pear shape | Hole | |

| Garrard 10a | Jan 1929 | Cast with flat steel base plate | Ball. Dial controlled | Winder moved to top. Floating spring case | Double | 1" x 0.026" | 16' 9" | Pear shape | Hub | |

| Garrard 10b | 1930 | Cast with flat steel base plate | Garrard patented. Side mounted governor adjustment. Above motorboard lever control | Floating spring case | Double | 1" x 0.026" | 16' 9" | Pear shape | Hub | |

| Garrard 11-old type | Pre-1927 | Cast iron | Ball. Dial controlled | Flat steel base plate | Double | 3/4” x 0.025" | 11' 6" | Pear | Hub | |

| Garrard 11 | Pre-1927 | Cast iron | Ball. Dial controlled | Shorter spring | Double | 3/4” x 0.0265" | 9' 3" | Pear | Hole | |

| Garrard 11a | 1927 | Cast iron | Ball later Garrard | Flat steel base plate | Double | 3/4” x 0.0265" | 13' | Pear | Hub | |

| Garrard 11b | 1930 | Cast iron | Garrard patented. Side mounted governor adjustment. Above motorboard lever control | Pressed steel base plate | Double | 7/8” x 0.026" | 13' | Pear | Hub | |

| Garrard 12 | 1927 | Cast with flat steel plate | Ball | Flat steel base plate | Single | 3/4” x 0.025" | 11' 6" | Pear | Hole | |

| Garrard 12a | 1929 | Cast with depression in steel plate for governor | Ball | Wider and longer spring | Single | 1” x 0.024" | 12' 6" | Pear | Hub | |

| Garrard 12b | 1930 | Cast with pressed steel plate | Garrard patented. Side mounted governor adjustment. Above motorboard lever control | Single | 1” x 0.024" | 12' 6" | Pear | Hub | ||

| Garrard 12bb | 1933 | Cast with pressed steel plate | Garrard patented. Side mounted governor adjustment. Above motorboard lever control | Brake added | Single | 1” x 0.024" | 12' 6" | Pear | Hub | |

| Garrard Junior | 1929 | Cast with pressed steel plate | Ball | Powerful budget model | Double | 3/4” x 0.0265" | 10' 6" | Pear | Hole | |

| Garrard Junior B | 1930 | Cast with pressed steel plate | Garrard Patented | Introduced twist governor control | Double | 3/4” x 0.0265" | 10' 6" | Pear | Hole | |

| Garrard 14 | 1930 | Cast with pressed steel plate | Garrard patented with Twist control | Columbia 14 | Single | 3/4” x 0.025" | 8' 6" | Pear | Hole | |

| Garrard 20 | 1930 | Cast with pressed steel plate | Garrard patented with Twist control | First mass produced spring motor | Single | 3/4” x 0.025" | 8' 6" | Pear | Hole | |

| Garrard 21 | 1930 | Cast with pressed steel plate | Garrard patented with Twist control | Budget model | Single | 3/4” x 0.025" | 11' 6" | Pear | Hole | |

| Garrard 24 | Cast with pressed steel plate | Budget model | Single | |||||||

| Garrard 30 | 1930 | Cast with pressed steel plate | Garrard Patented Twist control | In production for at least 24 years | Double | 3/4” x 0.025" | 8' 6" | Pear | Hub |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-th.jpg)

-th.jpg)